Bottom Seal Bag Machine

DESCRIPTION

This is a high speed bottom seal bag making machine uses a tubular roll of different sizes to make regular bottom seal bags and with other various attachments. LDPE , HDPE , PP materials can be used on this machine.

There are various models differentiated by Web width which one can select as per ones requirement.

FEATURES

- > High Speed up to 200 strokes/min.

- > Servo Motor for indexing and Accuracy

- > Microprocessor Controlled with Digital Display

- > Keyboard Setting for Speed, Size & Count

- > Backlit Display for Operating Parameters

- > Tension free Web for Strong Sealing

- > Photocell Control to convert Printed Rolls

ATTACHMENTS

The following optional attachments / tools are available to add features to the machine and make variety of bag structures:

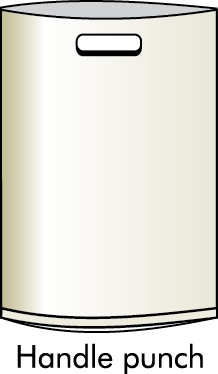

- > Handle Punch

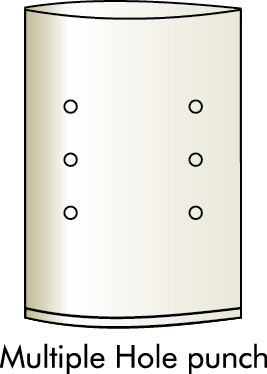

- > Hole Punch bank

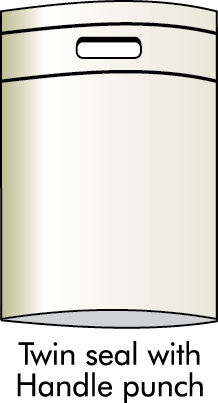

- > Twin seal with handle punch

- > Twin sealer for vest type bags

- > K-seal attachment

- > Double line or single line sealing type

TYPES OF BAGS THAT CAN BE MADE

SPECIFICATIONS

| Model | Max.Web | Draw Length mm | Max. Speed | Connected | Approx | Dimension |

| With mm | Max | Strokes/min | Load KW | Weight Kg | WxLxH cms | |

| BS 500 Delta | 460 | 700 | 200 | 6.0 | 1150 | 125x278x137 |

| BS 600 Delta | 580 | 900 | 170 | 6.5 | 1300 | 137x278x137 |

| BS 800 Delta | 780 | 900 | 150 | 7.0 | 1400 | 157x278x137 |